|

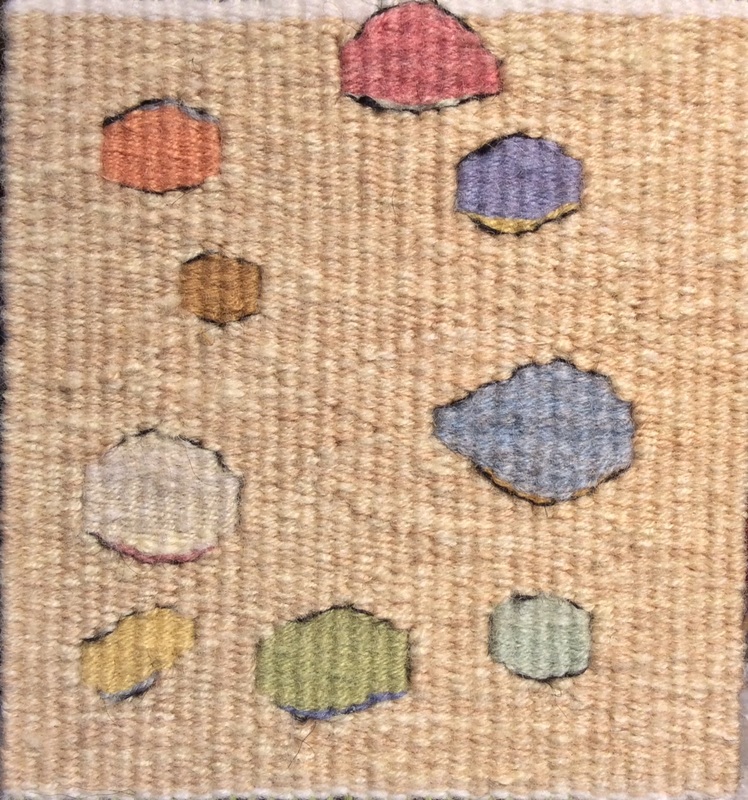

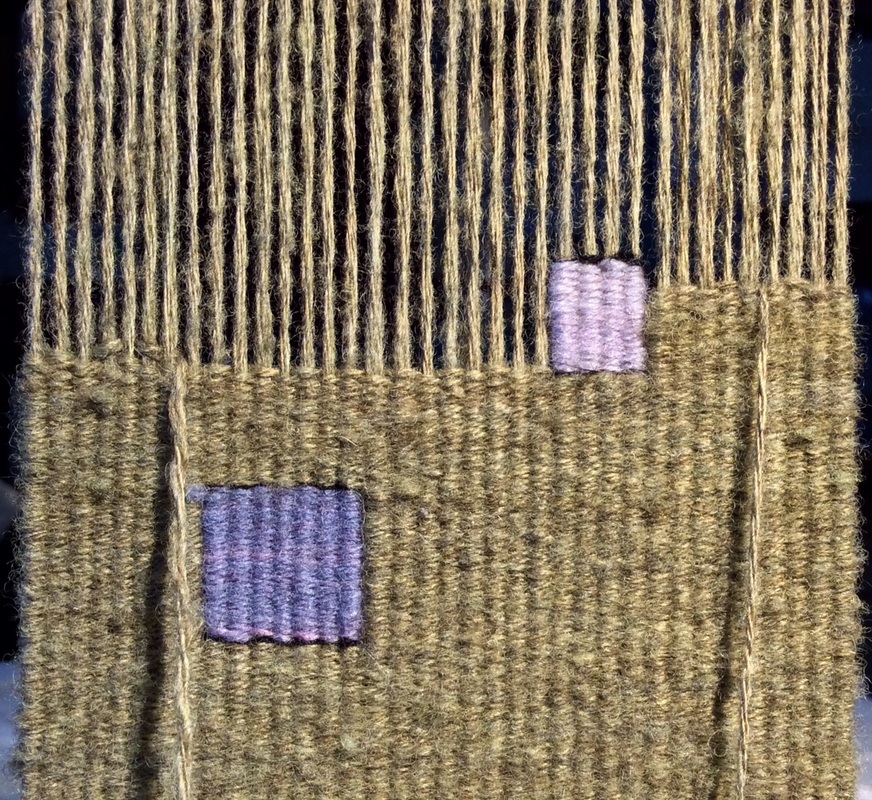

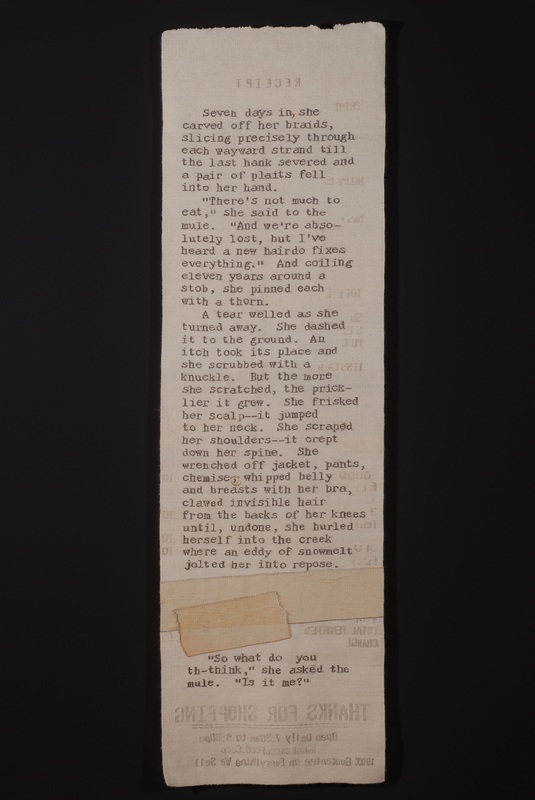

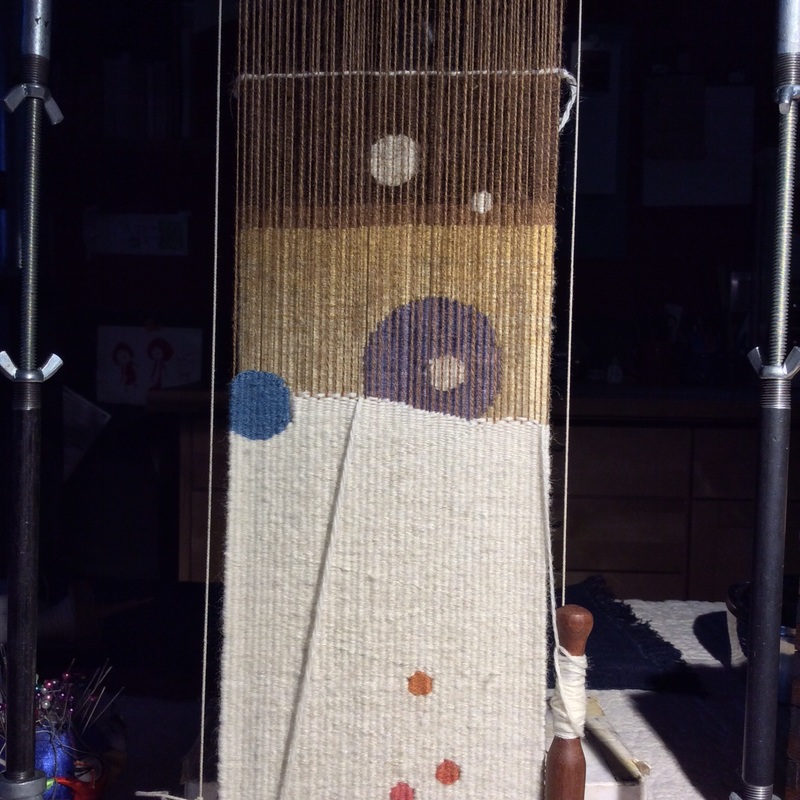

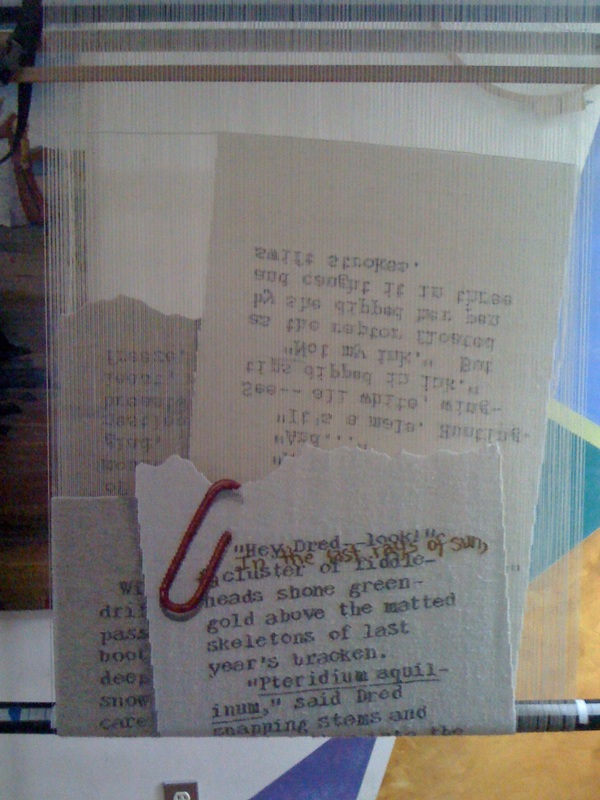

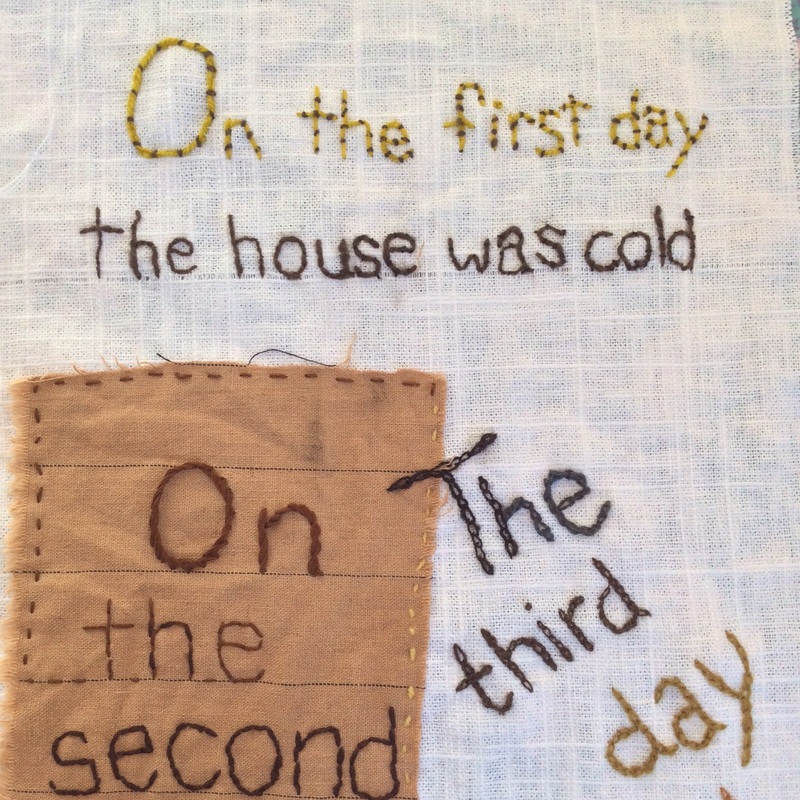

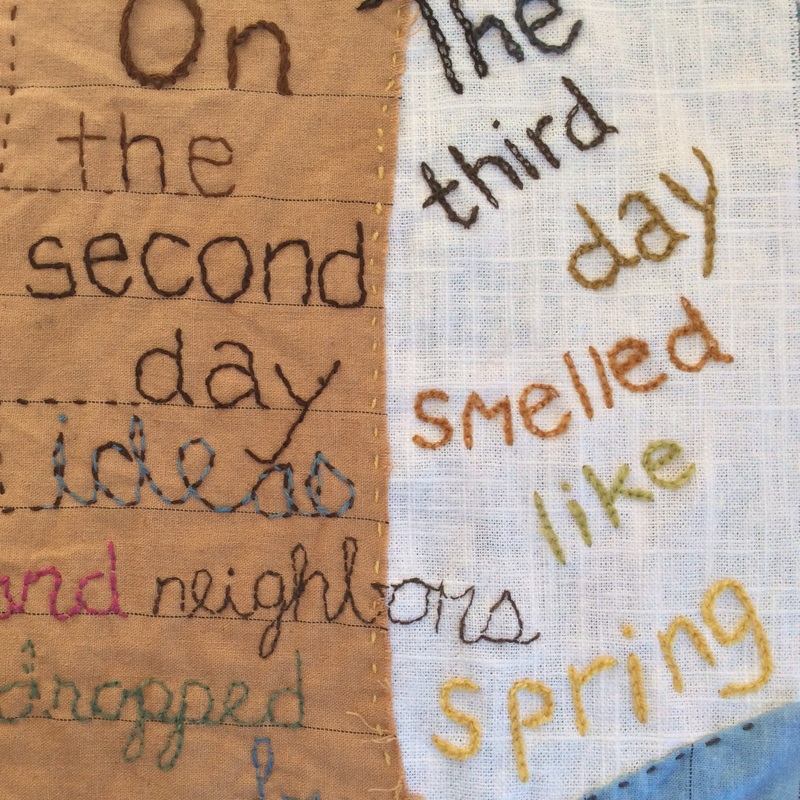

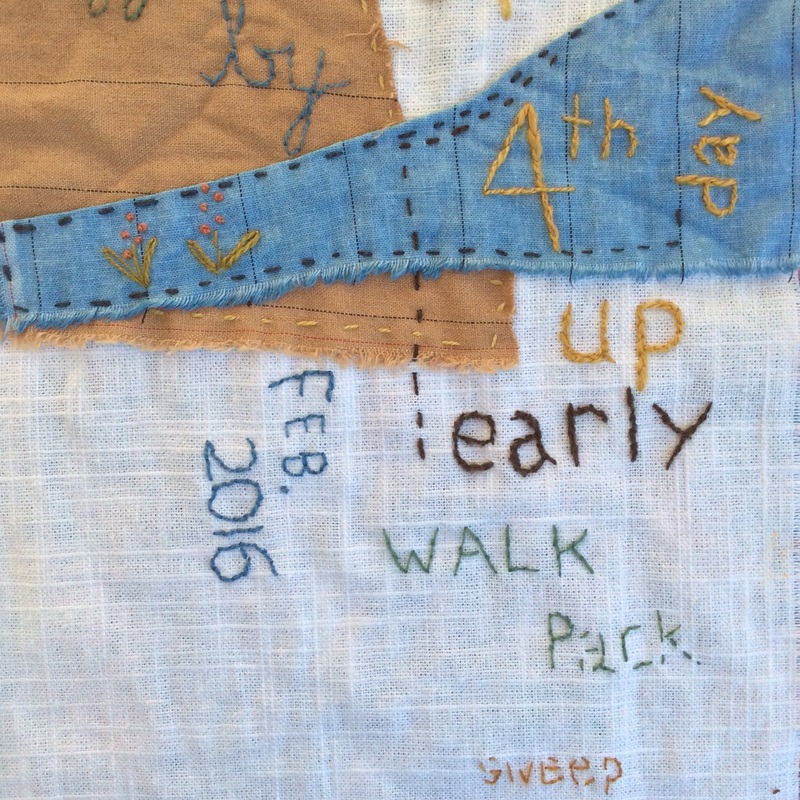

I don't know what to say about the little tapestries I'm weaving right now. So I guess I'll just hold on tight and let them go where they will.

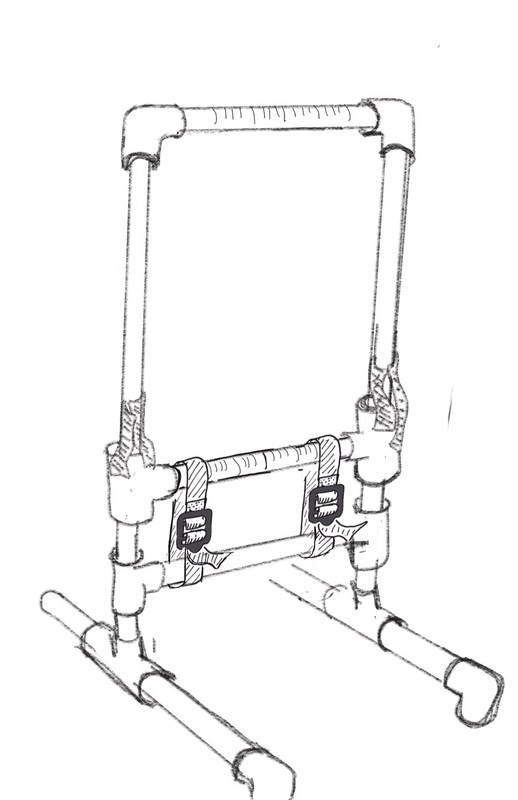

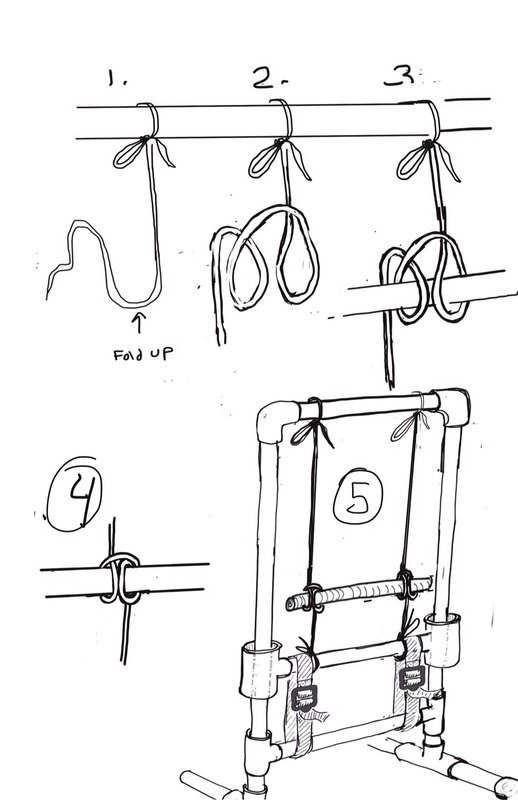

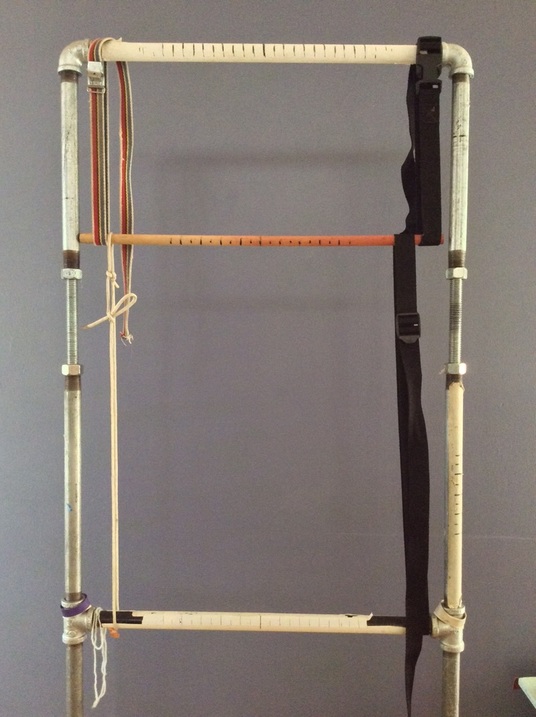

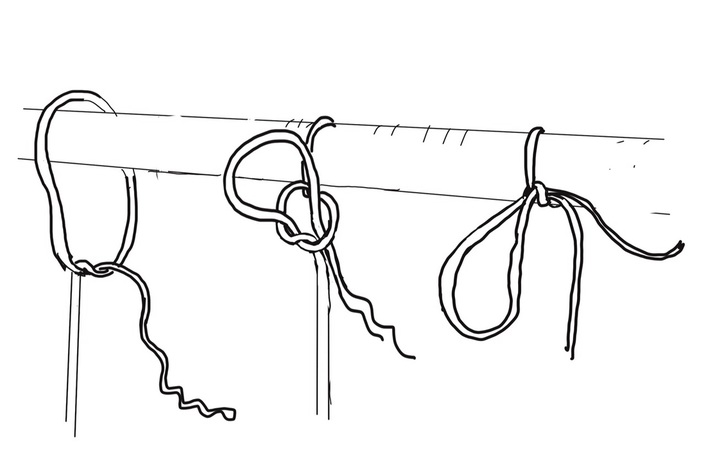

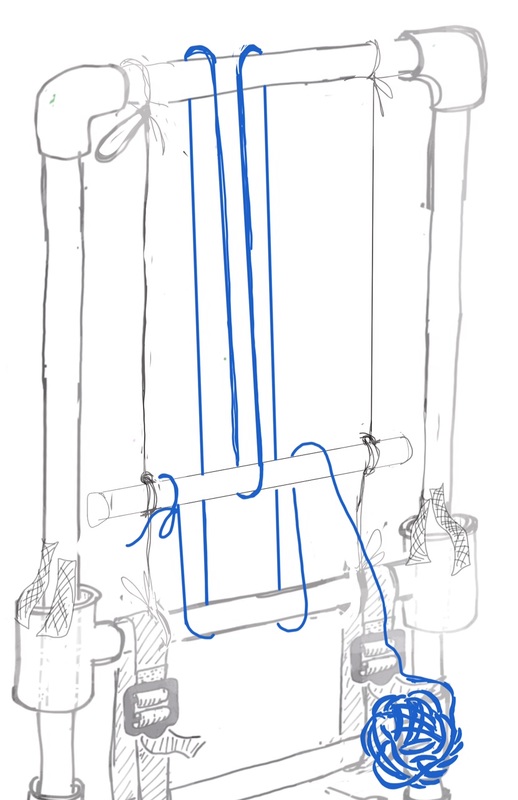

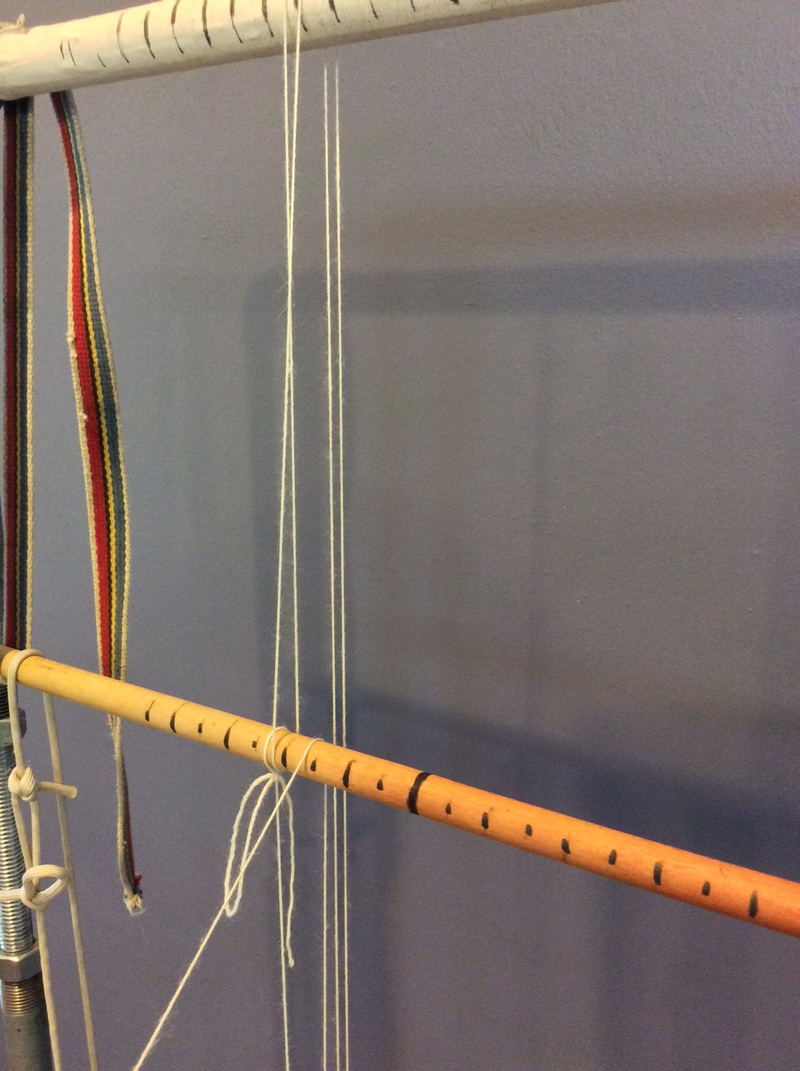

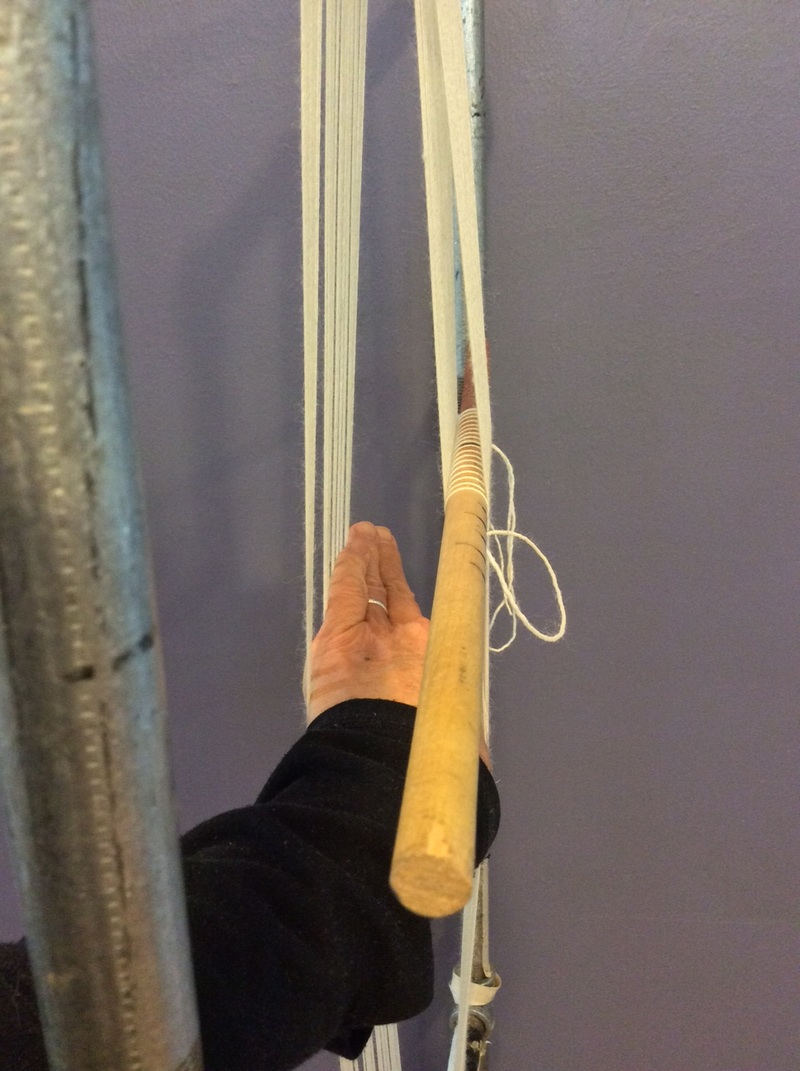

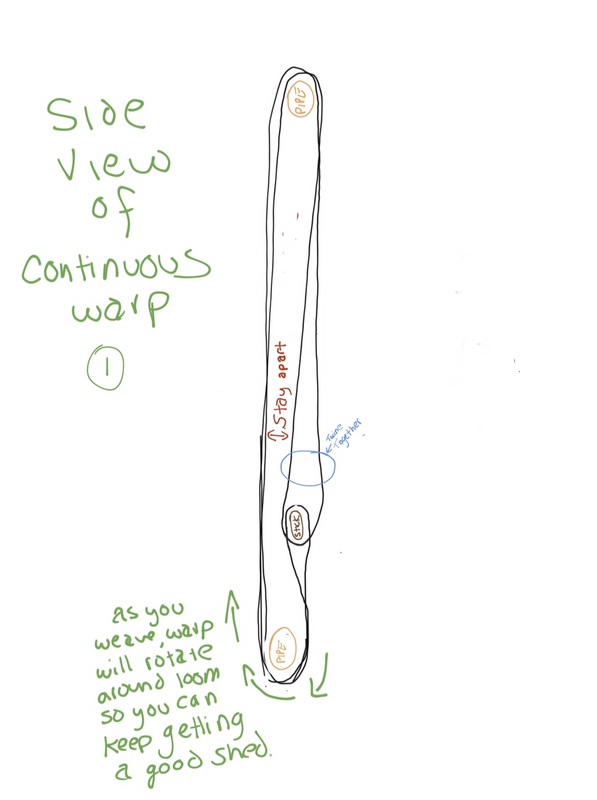

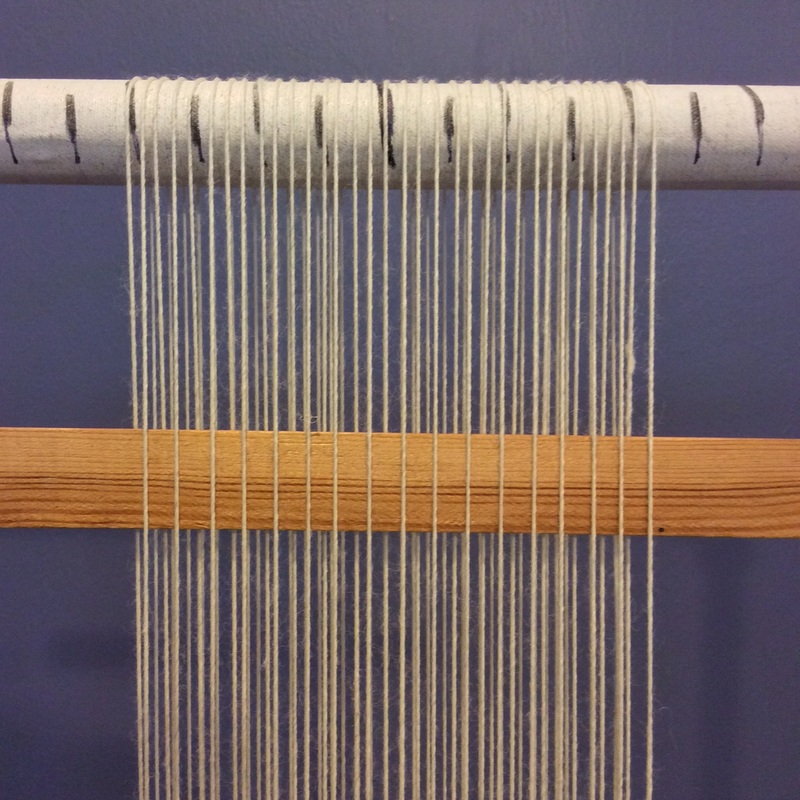

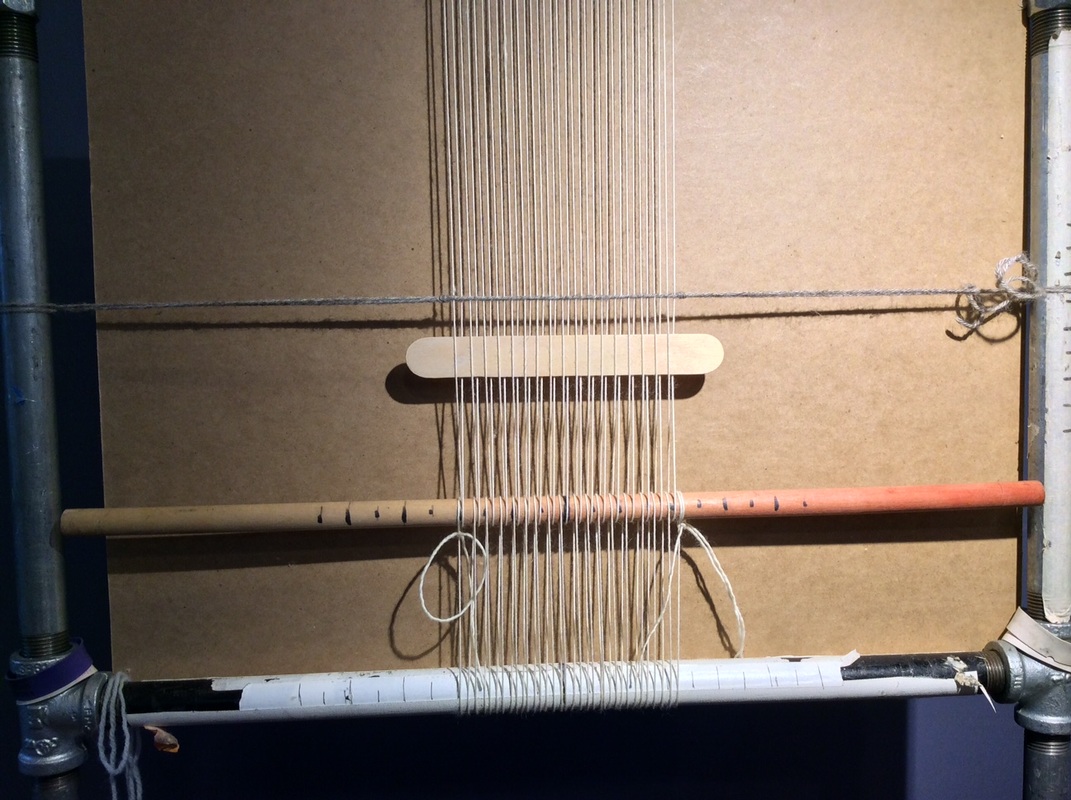

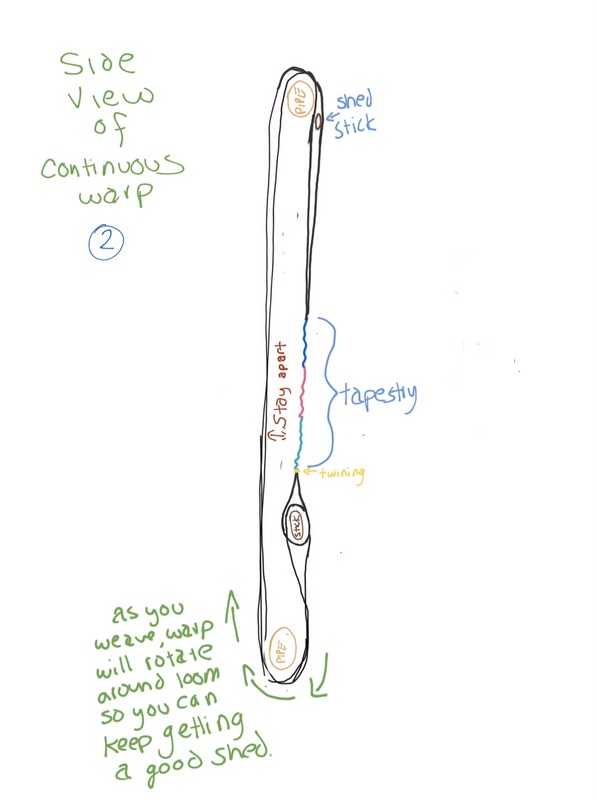

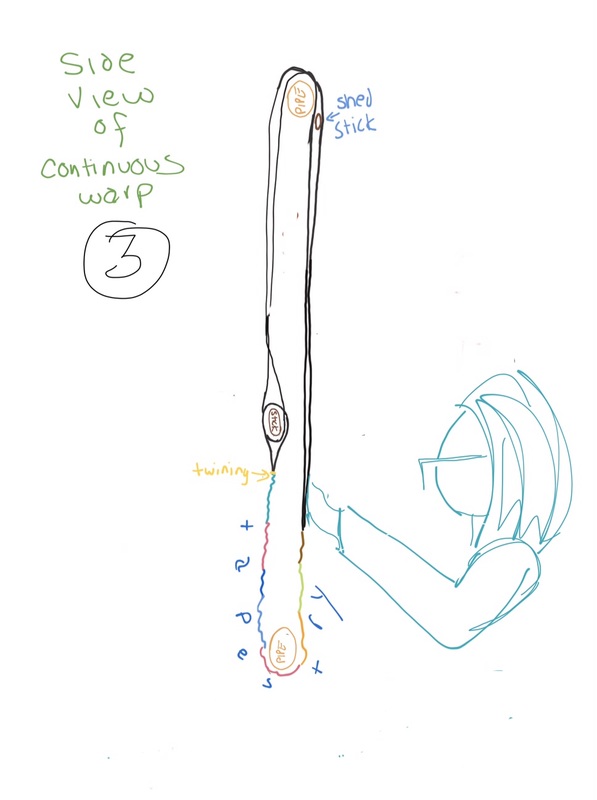

Or: Continuous Warping on a Tensioned Frame WHY? 1. The warp circles around the loom so you can weave something up to 1 1/2 times its height. 2. You get a good shed for the entire piece 3. Since the warp advances, you can keep the fell at a comfortable positon and avoid potential back/shoulder/arm pain You will need: -Frame loom (PVC, Copper, Galvanized etc) with tension device -Warp Stick: dowel 1/2 or 3/4 inch in diameter, approximately 1" shorter than inside width of the loom -Straps or string for suspending warp stick -Warp: yardage= circumference of weaving area (top to bottom plus an inch or two) x sett x warp width -Scissors -Tape 1. Set up loom a. Make sure it is square and that the tension mechanism is in a position that allows you to add (and perhaps also subtract), tension later. b. Mark warp stick and top and bottom bars of loom with increments of your choice (in or cm). I usually do the marking on a piece of tape so I can change it later. For a sett of 8 epi, the marks can be 1/8 inch apart 2. Position warp stick at a comfortable height for warping (eye level is good whether you are sitting or standing) and secure with string or straps. -Make sure it is level (or approximately level). Make sure your loom is level too... - check to make sure that the center of top bar, bottom bar and warp stick line up 3. Attach warp to stick with half bow to the left of center, half the planned width of your warp (i.e. for a 4" wide warp, tie two inches to the left of center). 4. Start Winding: a. Beginning at the warp stick, bring your yarn down and under the bottom bar of loom (front to back) -in the case of a PVC loom with straps see illustration above- b. All the way up the back and over the top bar (back to front) c. Down and under the Warp Stick (back to front reversing direction) d. Back up and over the top bar e. All the way down the back and under the bottom bar (back to front) f. Up and over the warp stick (back to front, reversing direction again) repeat from a. NOTE 1: for a sett of 8 dpi, warp strands will be 1/8" apart where they go over the top and under the bottom beams. On the Warp Stick the alternate loops will also be 1/8 inch apart -- try to keep warp evenly spaced (it is easier to deal with and to count this way), but exact positioning is not critical. You will have the opportunity to adjust later NOTE 2: check periodically to make sure the winding pattern is correct and that the yarn running up the back does not cross over to the front. If you have accidentally done this, unwind to that point and redo it Continue in this pattern until you have the number of warp ends you need. one full repeat makes two warp ends Temporarily tie or tape the end of the yarn to the warp stick before adjusting tension. A double half hitch works well as you can take up the slack without untying it. 5. Adjust tension: Pull on the first strand on one side above the warp stick, then on the adjacent one below the stick to take up slack. Repeat across. Then do it again -- not to make it more tight, but to make it more even. Run your fingers lightly across the warp at the back; when you are done it will feel even and all the strands should stop wiggling at about the same rate. Tie the end firmly to the warp stick. (I use a half bow again) 6. Adjust position of loops on the warp stick The loops should be 1/8" apart (one facing up, 1/8 inch space, then one facing down). 7. Remove string/ straps holding stick in place and pull down on the stick, sliding it closer to the bottom of the loom (approx 4 inches above the bottom beam). Note how the warp rotates around the loom. If you have made the warp very tight, you may have to release a little bit of tension to do this. When it is in position, tighten tension so it stays put. NOTE: On a frame loom without an intrinsic tension device it might be possible to add tension by using shims -- sticks shoved between the warp and the top and bottom parts of the frame -- to add and release warp tension. 8. Adjust position of warp at top and and bottom beam. 9. Make sheds: Slide a shed stick/dowel in above the warp stick and push it to the top of the loom. Warp should alternate over and under the stick. Weave in a second stick (tongue depressor for a narrow warp) just below in the opposite shed. (You can slide a piece of paper/ cardboard between layers of the warp so the back (stored) warp isn't too distracting while you do this. Push tongue depressor/second stick down until it is about 3 inches the warp stick to bring layers together 10. Twine -- Twining holds the layers together and fixes the sett - Cut a strand of warp 2 1/2 X the width of your loom, -Attach it to the left side bar of the loom using a larks head knot -Tie an overhand knot at the left side of the warp to keep it in place Twine across: --Slip one twining strand behind first warp and out to the front --Bring the second twining strand over the first, behind the next warp and out to the front --pick up the first twining strand again, bring it over the second one and behind the next warp. Continue across. Note that the two twining strands twist around each other between each warp. If you are working with a fine warp, the sett may become too close. In this case, twist the two twining strands twice around each other between each warp to create more space.

11. Half Hitches with craft thread Before starting to weave, I tie double half hitches around each warp end just above the twining. This makes extra sure that the tapestry stays in place when it is cut from the loom. When the tapestry is done, I repeat the double half hitches at the top before cutting off. Now start weaving as you would on any warp. When the fell gets uncomfortably high, advance the warp by loosening the tension on the loom and moving the warp stick until the fell is again in a comfortable position. The stick will soon slide under the bottom bar of the loom (this needs a VERY loose warp), and then continue up the back over time as you advance the warp. I usually stop before the stick comes back over the top bar, but it is possible to keep going as long as you can make a shed. Well, I think that's it!

Hope things are clear for those who want this info. Most of this is repeated in a slightly different form in my book Kids Weaving, so if you have the book, you're all set. Happily it is due to be re-issued in the spring of 2017 so then I can just refer to it Next week I plan to be back to my usual meanderings. Nuff with the instructions, eh? and a bit of shameless promotion!  The Palette Box: Its perfection is clear even if the photos are not.  The Hepty Seven Sided high whorl spindle 1. It won't roll of the table 2. It doesn't need a notch (those facets do the job) 3. It is fast-- a quick roll up a leg and then it flies 4. It goes and goes and goes 5. It is Balanced (straightens with a touch of the knee should it ever wobble). 6. The Shaft is buttery to the touch but with enough friction to really get going. 7. It is sturdy and short enough to spin while sitting in a chair 8. It turns the previous-pair-of-spindles-I-use into a group of three

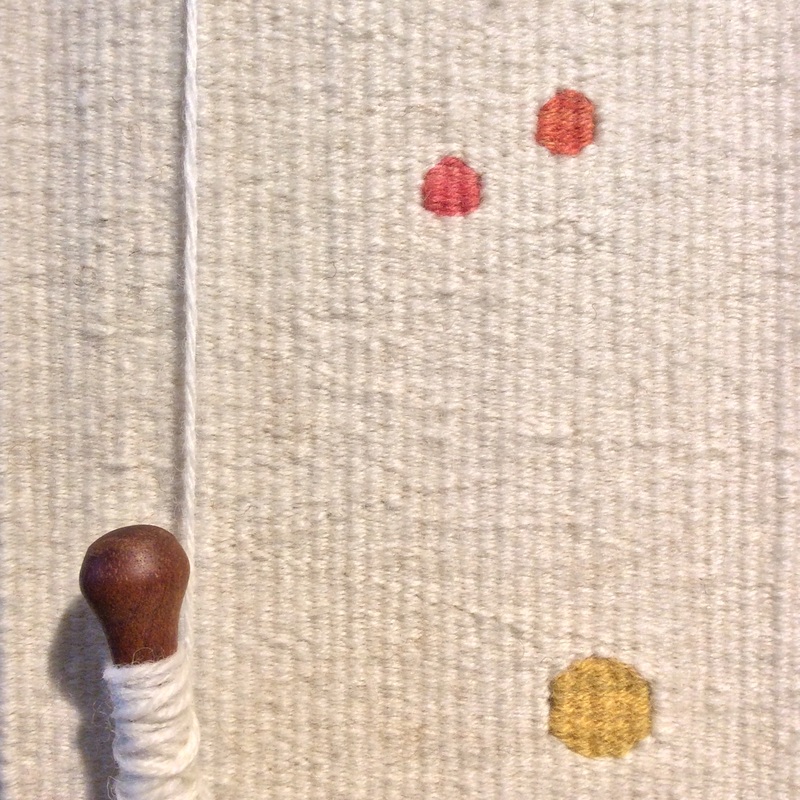

Plying Stick -- This simple object might be as self-explanatory as a Palette box, but I'm going to blather a bit nonetheless because mine, at first, looked more like a fragment of a Ponderosa Pine struck by lightning than an essential and life changing tool. But first, I have to back up a few steps. Though a spindle spinner long before I touched a wheel, plying was always a pain in the neck: two ended balls (or separate balls), endless eyelashes, too much to juggle and everything twirling in a different direction. Then I met Ed Franquemont * and ever after have followed his simple advice: wind your singles together into a ball-- parallel but not twisted-- THEN add twist in a second step. The reasons this works are many but I will spare you my diatribe and say only that doing this one "extra" thing has turned plying frustration and eyelash hell into another pleasant part of the soul-satisfying process of making yarn with a spindle. *There are endless wonderful things to say about Ed Franquemont and all he shared with the textile community. To learn more, google him, spend time with his marvelous daughter Abby Franquemont and read her book Respect The Spindle Back to the stick thing. Winding the parallel strands of singles into a ball works pretty well for a two ply yarn, but a few years ago I wanted a spin-ply-knit-as-you-go project for some upcoming travel and decided a three strand chain ply yarn would be perfect. The stick (pictured below on the left), onto which I wound the chained (but untwisted) singles turned out to be the answer to an unasked question, and has become my go-to tool for all spindle plying no matter the number of strands. Both the winding and the subsequent unwinding, are easier than ever.  So that's all it is, actually a stick for holding yarn while you ply. Almost silly to say all this stuff about it, except I want to rave about Alexandra Iosub's version which takes my simple chunk of unburned firewood to a whole new level of plying pleasure. Alex's sticks -are balanced and lovely to hold while winding -keep the strands in place (no accidental sliding off one side) -unroll in the hand with smooth and sensual pleasure as the spindle twirls toward the ground -are available in her Etsy store! A quick overview of chain plying with a spindle Using the singles straight off of your spindle: 1. fold the end of the singles into a loop, 2. pull another loop of singles through that loop (length can vary -- I like to make my loops 12 - 18 inches long unless I'm adjusting for color) 3. stick a finger through the new loop and hold the 3 strands taught (two strands of loop + the singles going to the spindle) and wind onto the stick. 4. When your finger holding the loop gets close to teh stick, pull another loop through it. 5. When your spindle is empty and your stick full, start adding twist with the spindle. Do any of you use a plying stick? Have you seen one? I think it must be what Elizabeth Zimmerman called an 'unvention.' Oh golly, and one more thing! The Classes are set for the Palouse Fiber Festival

Descriptions will be up soon, and Registration Opens 1 March. See you next week! |

Sarah C Swett

|